Hyris DNA

Food identity uncovered, one test at a time

The Hyris platform offers the disruptive capability to perform genetic analysis of biological samples in any kind of setting.

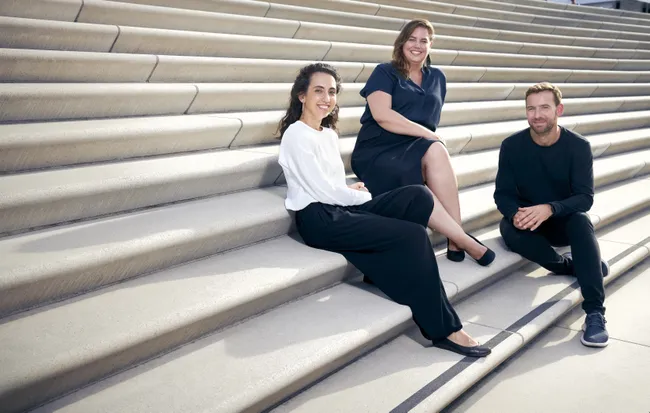

Entrepreneurs

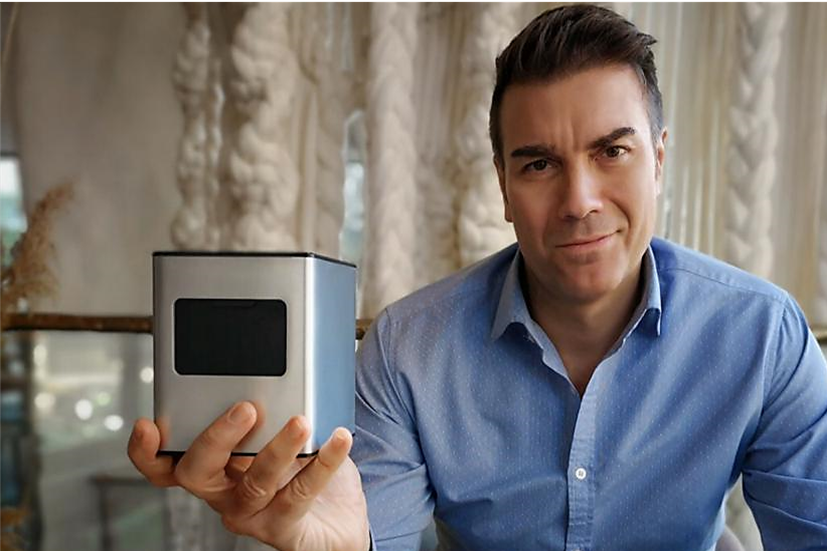

Stefano Lo Priore

Founded

2014

Partnered

2019

HQ

Milan, Italy

Category

Connecting the Value Chain

From olive oil to viruses, Hyris is providing safety and reassurance

With as much as 10% of all foods we consume tainted by adulteration, food scandals are on the rise all over the world (Source: Federation of American Scientists). As more and more leading food companies suffer supply chain disruption and reputational damage, so too has their leadership become laser-focused on quality assurance and supply chain transparency.

Hyris offers distributed genetic testing that’s more convenient and scalable than existing options. Hyris aims to create global impact by providing the industries it serves, the first at-scale library of food safety data. It does this through its distributed network of bKITS (bespoke sets of reagents for specific DNA sequences) and bCUBES (a miniaturized portable device).

Hyris has focused its application on the nutrition sector, while also working with adjacent and complementary fields, such as pharmaceuticals, virology and epidemiology. In recent months, Hyris has been granted major regulatory authorizations for COVID-19 testing, including a ground breaking approval for point of care diagnostics by Health Canada.